The performance and safety of EV batteries relies on multiple factors. While there are many parameters that need to be controlled in EV battery assembly and manufacturing, the contact resistance between the individual cell and the connection tab is the most crucial factor determining the performance and safety of EV batteries.

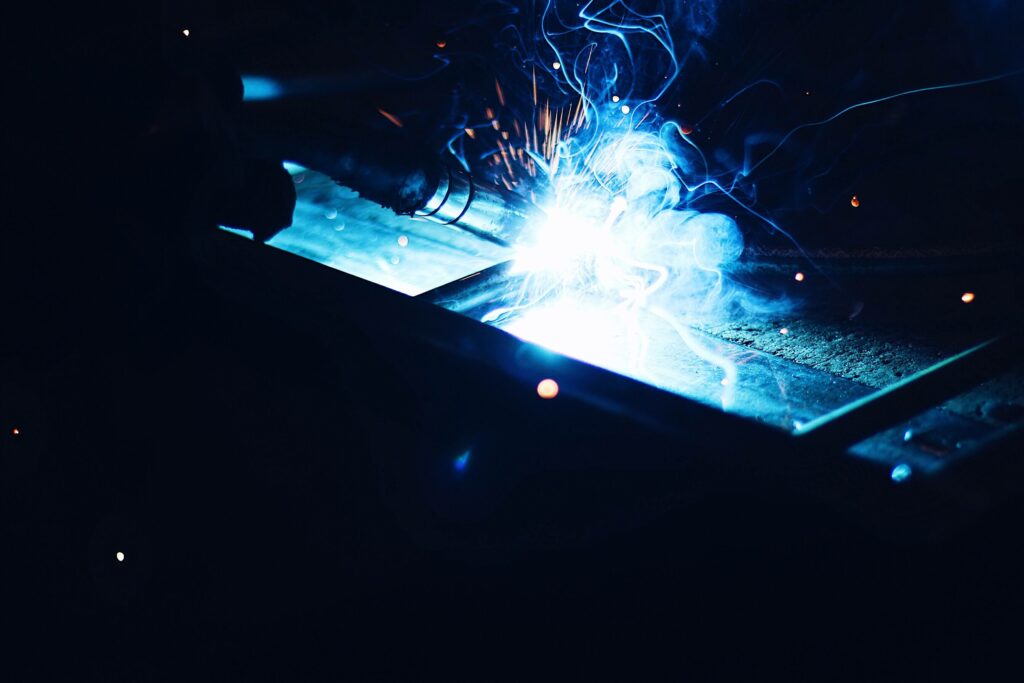

Welds are the bottleneck in any EV battery’s electrical circuit. A sufficiently large weld area is essential to ensure the least possible resistance and the flow of required current without undue heating.

Various weld technology options are available and the decision to choose between them depends primarily on the production scale, battery cell geometry, and budget considerations. A host of parameters then determine the overall efficiency and throughput of the chosen welding technology.

We’ve prepared an in-depth Whitepaper delving into the various welding technology options for EV battery assembly, so that you can make the right choice for your EV manufacturing business.