Technical Specifications:

- Capacity - 800 JPH

- Module Types - 6

- Compressed Air - 20 cfm @ 6 bar

- Footprint - 5 x 3.5 m

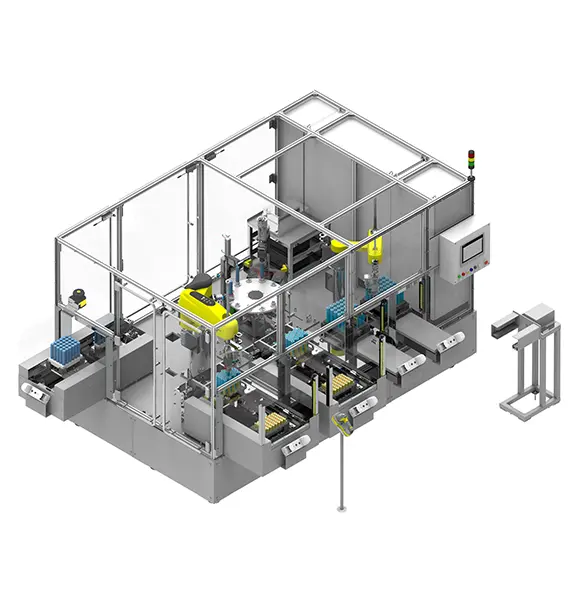

Cybernetik’s Single Cell Sorting System is EV battery assembly automation that handles one cell at a time using pick and place robots, barcode scanner, electric parameter tester, and alternate cell vertical inverter. The setup uses a rotary table for efficient space utilization. Capable of handling multiple cell variants with minimal changeover, the system can form 6 types of modules. Cells are tested individually for open circuit voltage (OCV) and AC internal resistance (ACIR). The system is designed for high-speed, continuous operations with quality control and traceability to support efficient and rapid electric vehicle manufacturing.

Working of the single cell sorting system begins with the operator using the manual inversion station for rapid cell loading from box to holder. Next, the operator loads the holder at the common entry/exit station and scans it manually for traceability. The input pick and place robot then transfers the EV battery cells one-by-one to the rotary table for barcode scanning, OCV and ACIR testing, and alternate upside-down inversion. Another pick and place robot executes quality control by placing accepted cells into the output cell holder. A cell template above this holder guides the robot and minimizes its vertical movement for high-speed operations. Multi-stacking of two cell holders i.e. placing them one below the other at the common entry/exit station enables operational continuity. The quality control robot also transfers rejected EV battery cells to a different holder, ensuring the use of defect-free cells in electric vehicle production.

Project Video

Cybernetik Solution

- Productivity: Manual inversion station, cell template for loading, multi-stacking of cell holders, and alternate cell vertical inversion cut cycle time.

- Traceability: Cell holder and single cell scans for track and trace.

- Quality: Rejection of defective EV battery cells.

- Customizable: Recipe selection for 6 types of module formation.

- Flexible: Multiple cell types handled with minimal changeover.

- Compact: Rotary table minimizes footprint.

0+

Systems Installed Worldwide

0+

Satisfied Customers