We develop efficient Turnkey Solutions for your food business

"*" indicates required fields

Cybernetik is an industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the food, pharmaceutical, chemical, and manufacturing industries across the world.

Cybernetik was set up as a consultancy in 1989 by a group of engineers from the Indian Institute of Technology (IIT)-Madras, India and the State University of New York at Buffalo, USA.

From 10 people operating in less than 100 sq.m. workspace, our footprint in India has expanded to 30,000+ sq.m. across four units, two each in Pune, Maharashtra and Nadiad, Gujarat. Cybernetik's cooking kettles, an integral part of their ready-to-eat food manufacturing automation solutions, offer precise temperature control and efficient cooking processes to produce high-quality food products.

Our global operations are based out of three international offices:

Vietnam (for Southeast Asia), Dubai (for Middle East and Africa) and United States (for North America).

Food production automation delivers an absolutely critical requirement for the food industry – reduction of bacterial load. Considering that recalls are the worst profitability killers in the industry, and that the chances of bacterial contamination are very real, automation of the food manufacturing process is crucial for the industry.

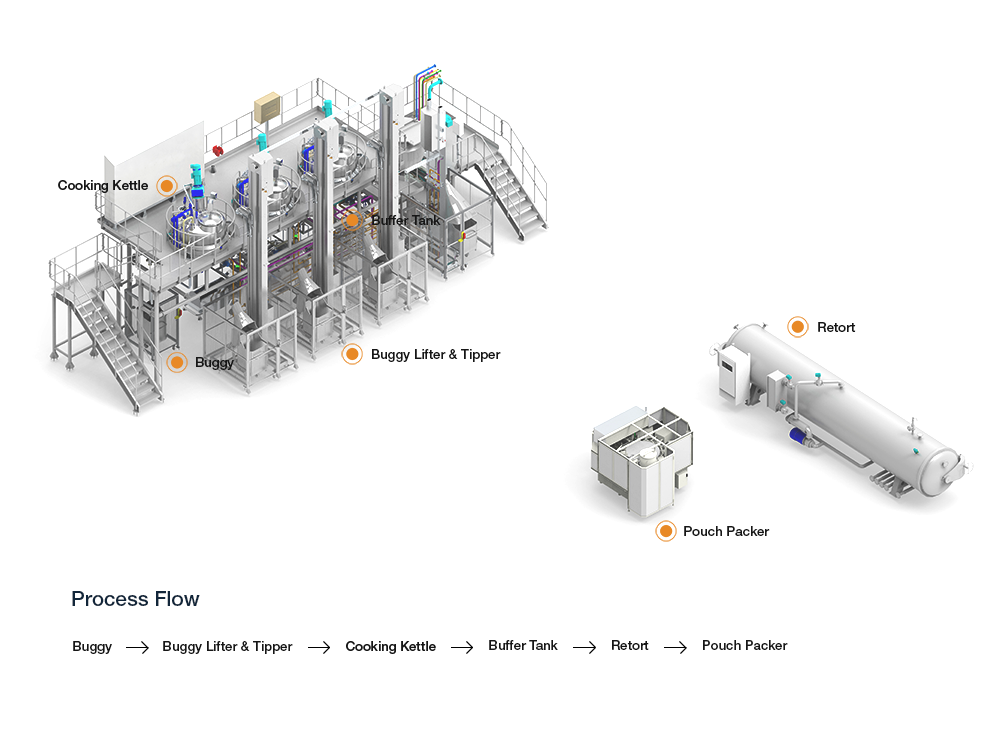

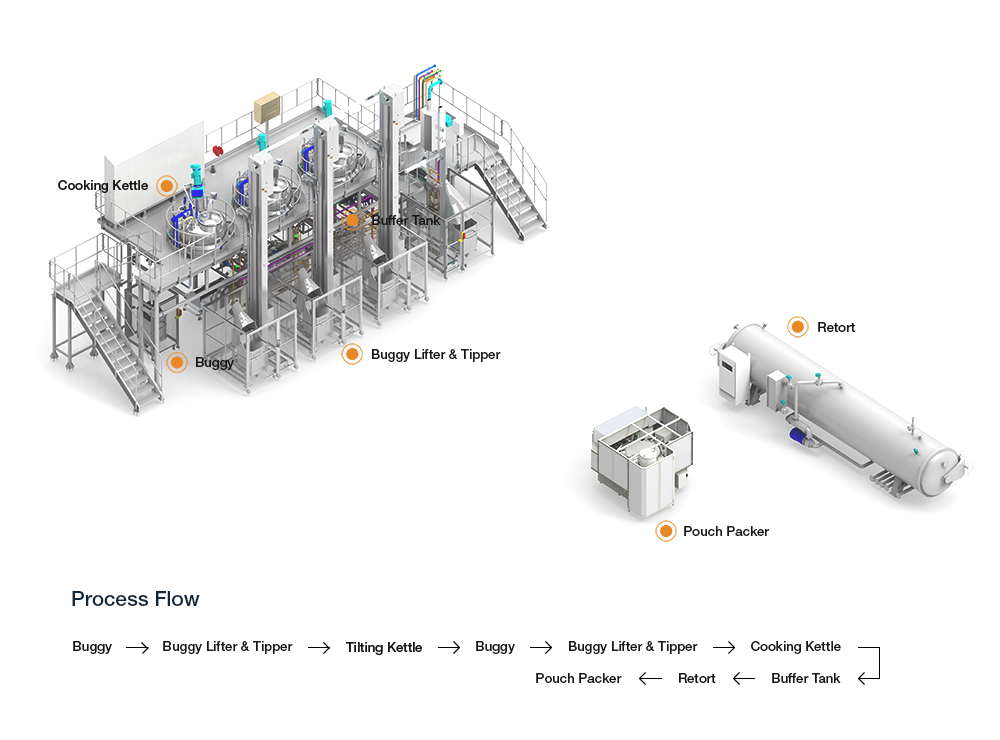

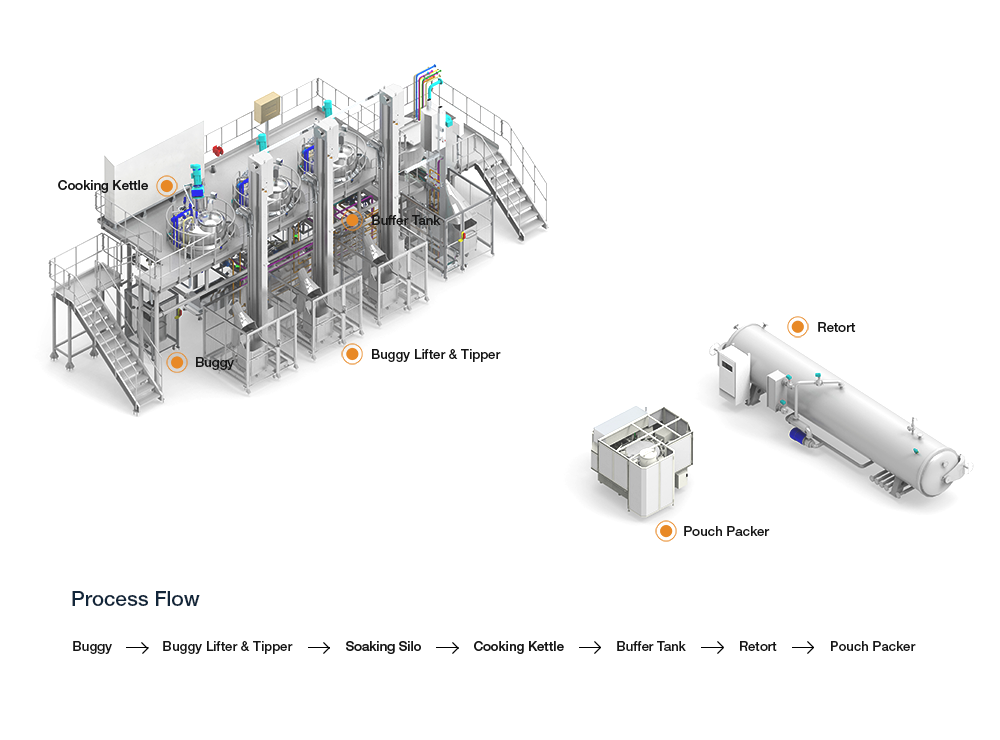

Cybernetik Technologies automates the food manufacturing process as well as the food packaging process. One of our food production automation is the Industrial Cooking Line. Cooking Kettle is central to this automation, and it delivers rapid cooking without loss of nutrients or flavor. Raw material loading, cooking, buffering, and packaging is automated for high productivity, efficiency, safety, and cost effectiveness.

Food processing automation companies have their task cut out to ensure that hygiene is maintained at all stages of the production process. This is of course in line with the stated requirement of minimizing the bacterial load. One way of doing this is to have automated and directly connectible CIP (Clean in Place) system linked to the food processing equipment.