We develop efficient Turnkey Solutions for your chocolate business

"*" indicates required fields

Cybernetik is an industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the food, pharmaceutical, chemical, and manufacturing industries across the world.

Cybernetik was set up as a consultancy in 1989 by a group of engineers from the Indian Institute of Technology (IIT)-Madras, India and the State University of New York at Buffalo, USA.

From 10 people operating in less than 100 sq.m. workspace, our footprint in India has expanded to 30,000+ sq.m. across four units, two each in Pune, Maharashtra and Nadiad, Gujarat.

Our global operations are based out of three international offices:

Vietnam (for Southeast Asia), Dubai (for Middle East and Africa) and United States (for North America).

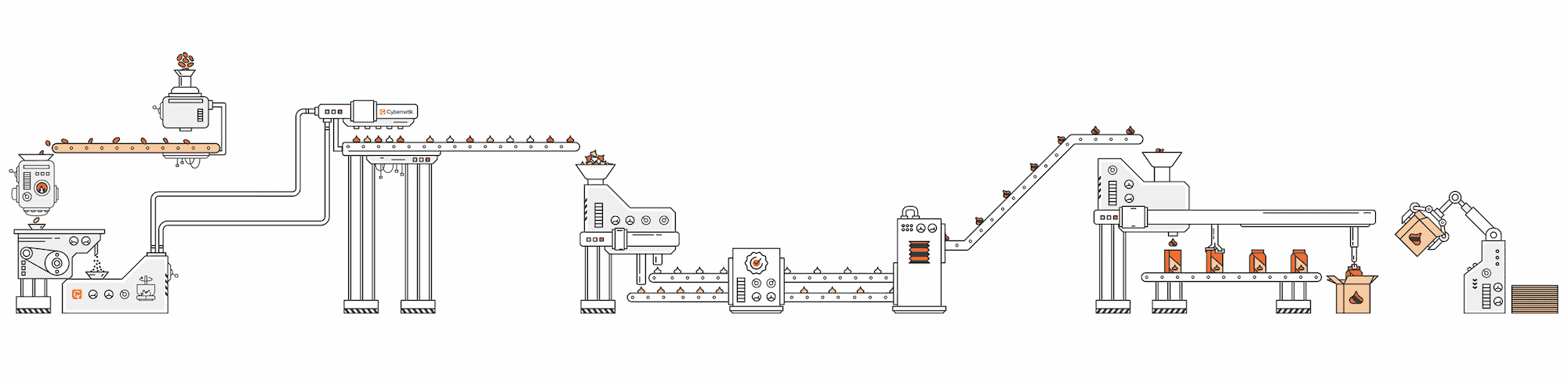

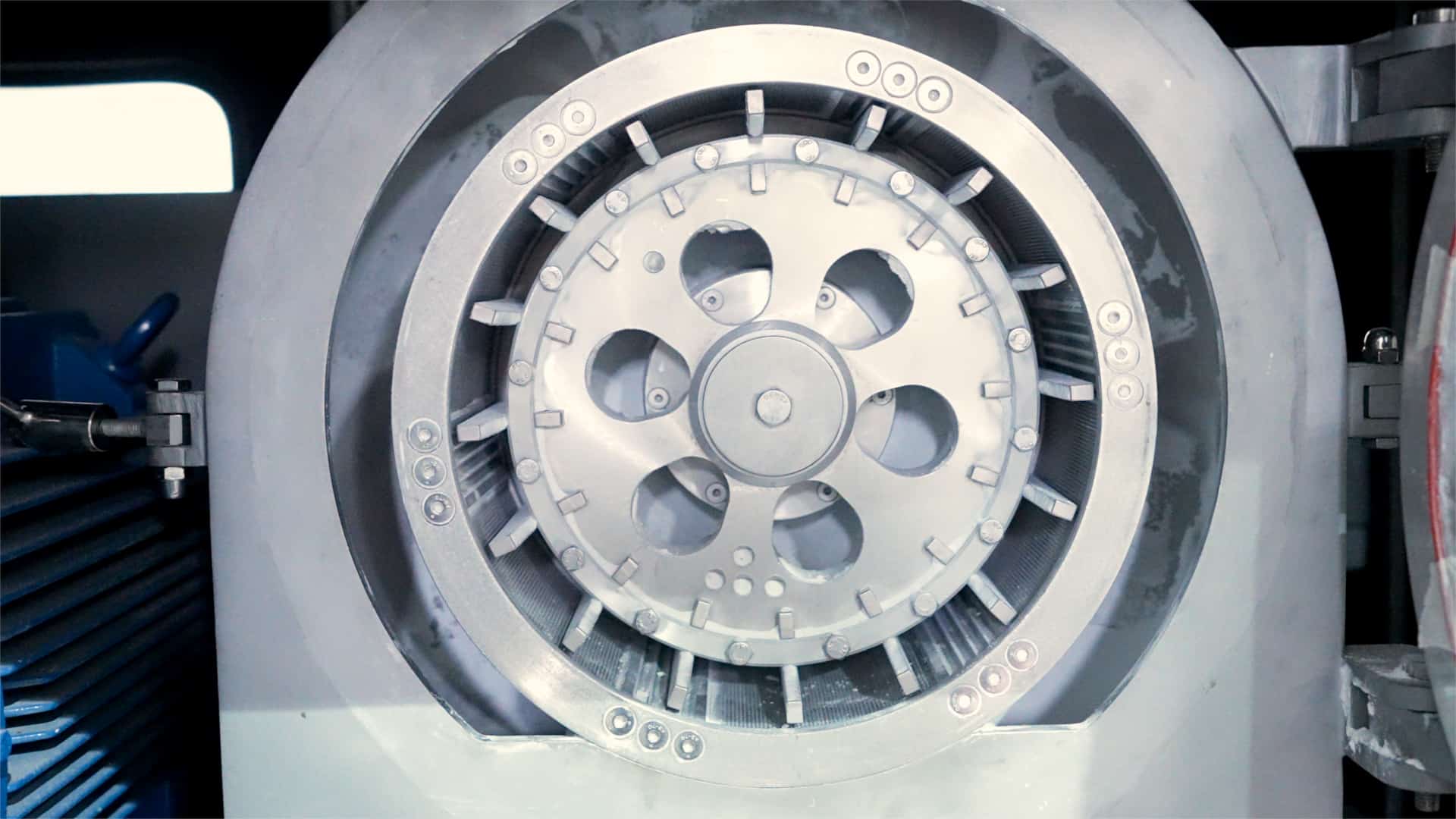

Chocolate manufacturing is a colossal global industry as chocolates are among the most popular of non-food items. Therefore, it doesn’t come as a surprise that chocolate manufacturing machines are in great demand. Top quality chocolate making machines enable fine control over temperature, mixing rate, and cooling rate. In turn, this allows close control over the two properties that determine the quality of chocolates – flavor and texture. For a chocolate making machine, Cybernetik offers advanced technology to streamline your chocolate production process.

Following is the process of manufacturing chocolates: