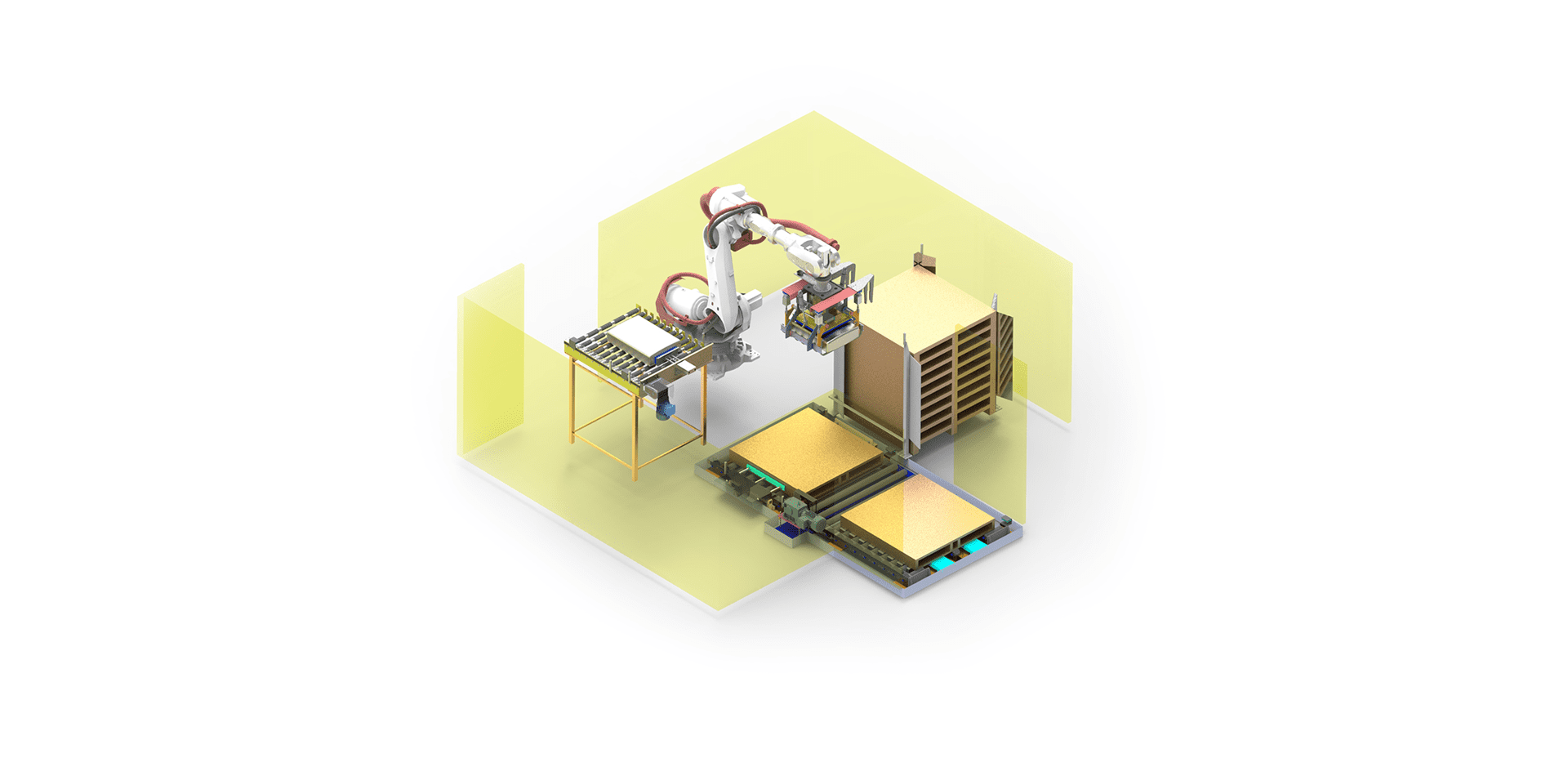

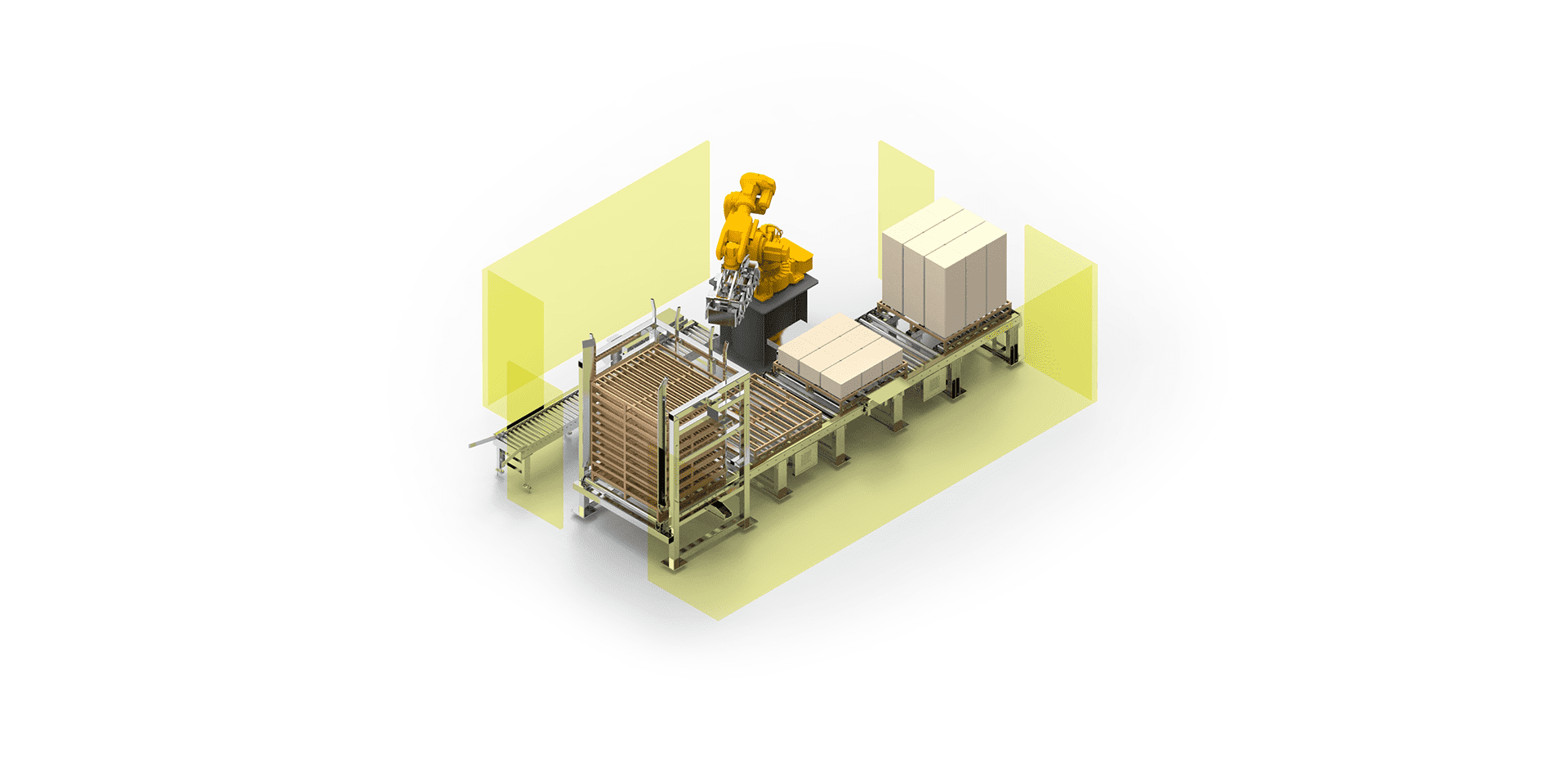

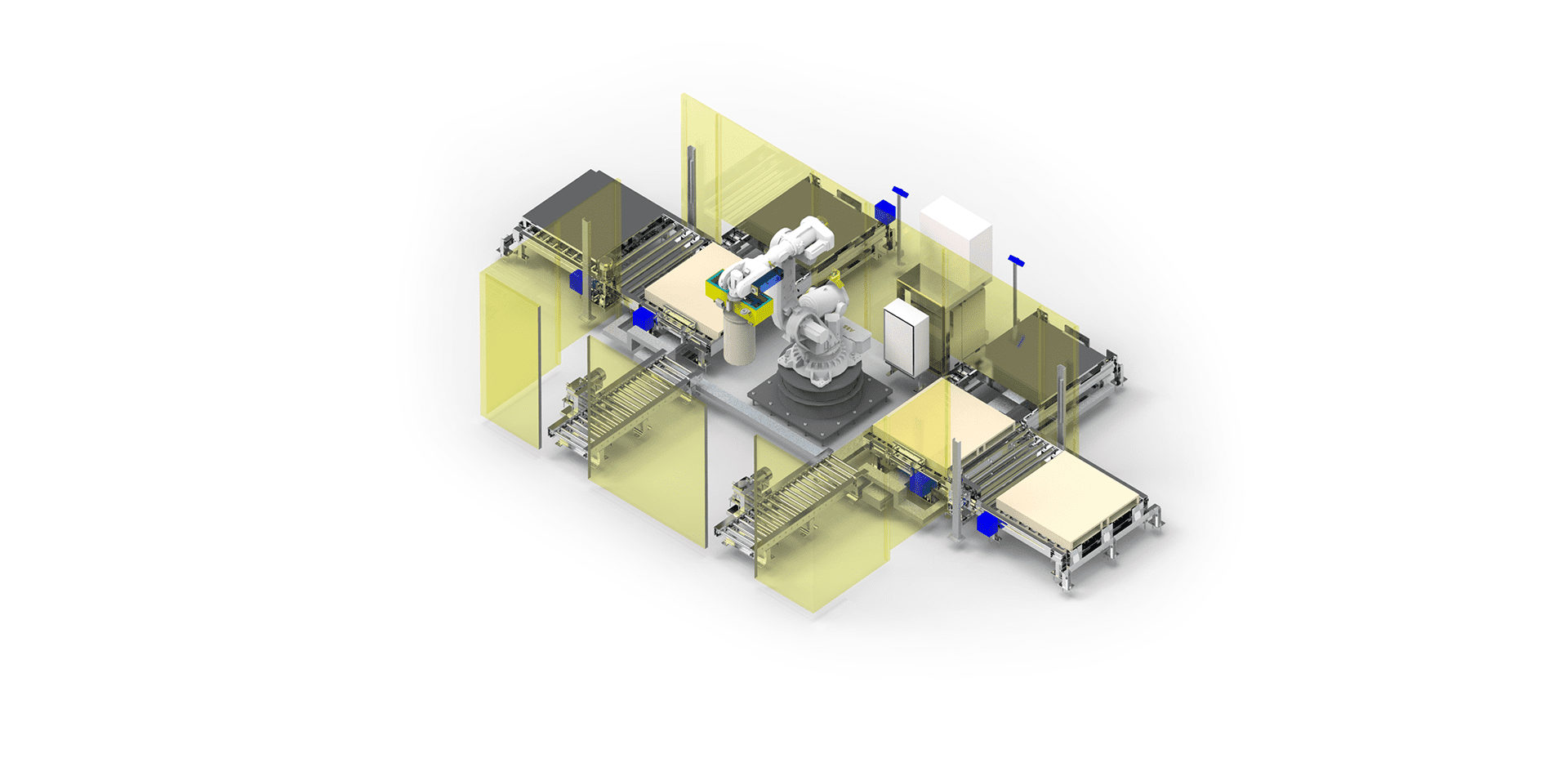

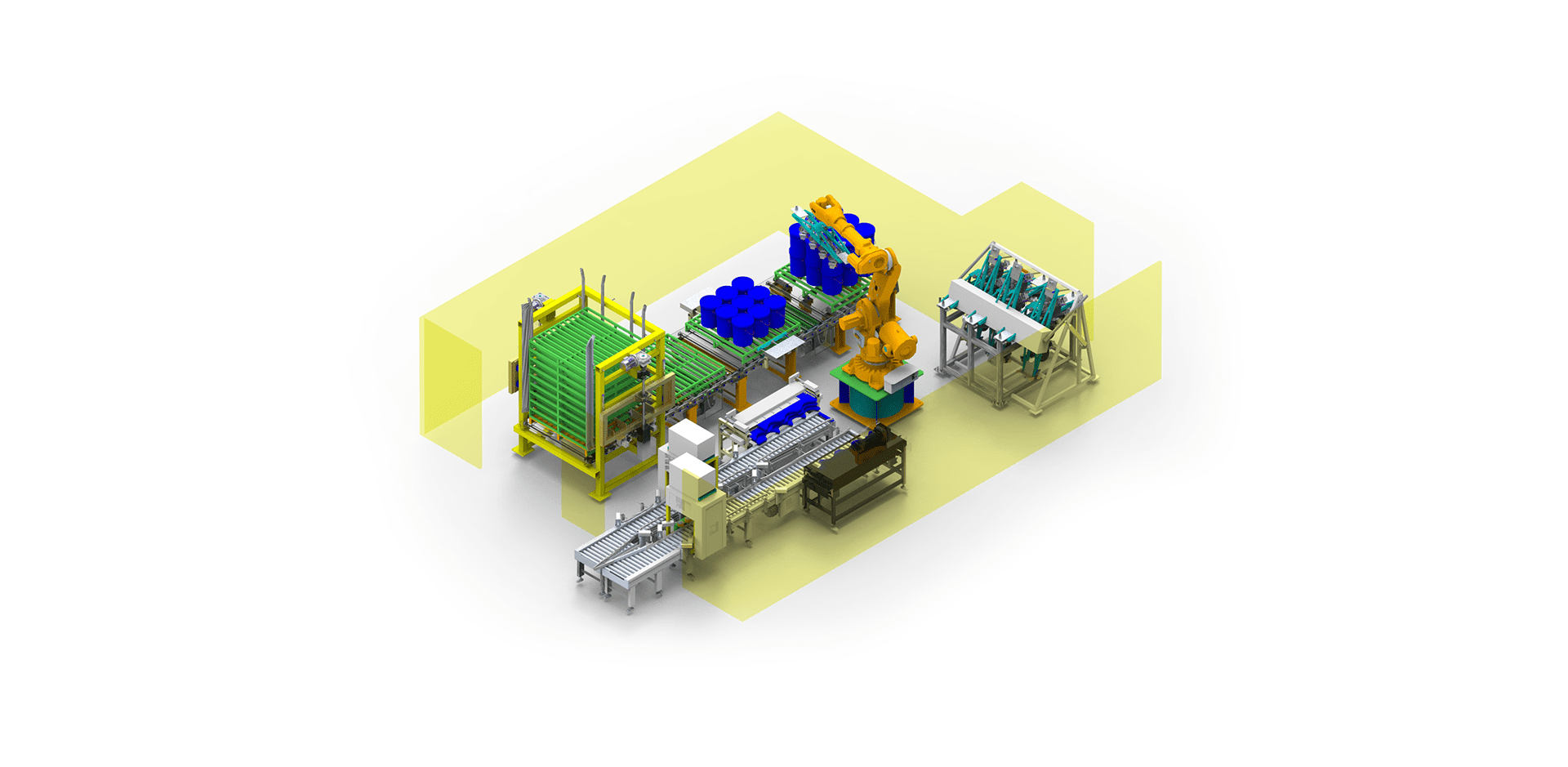

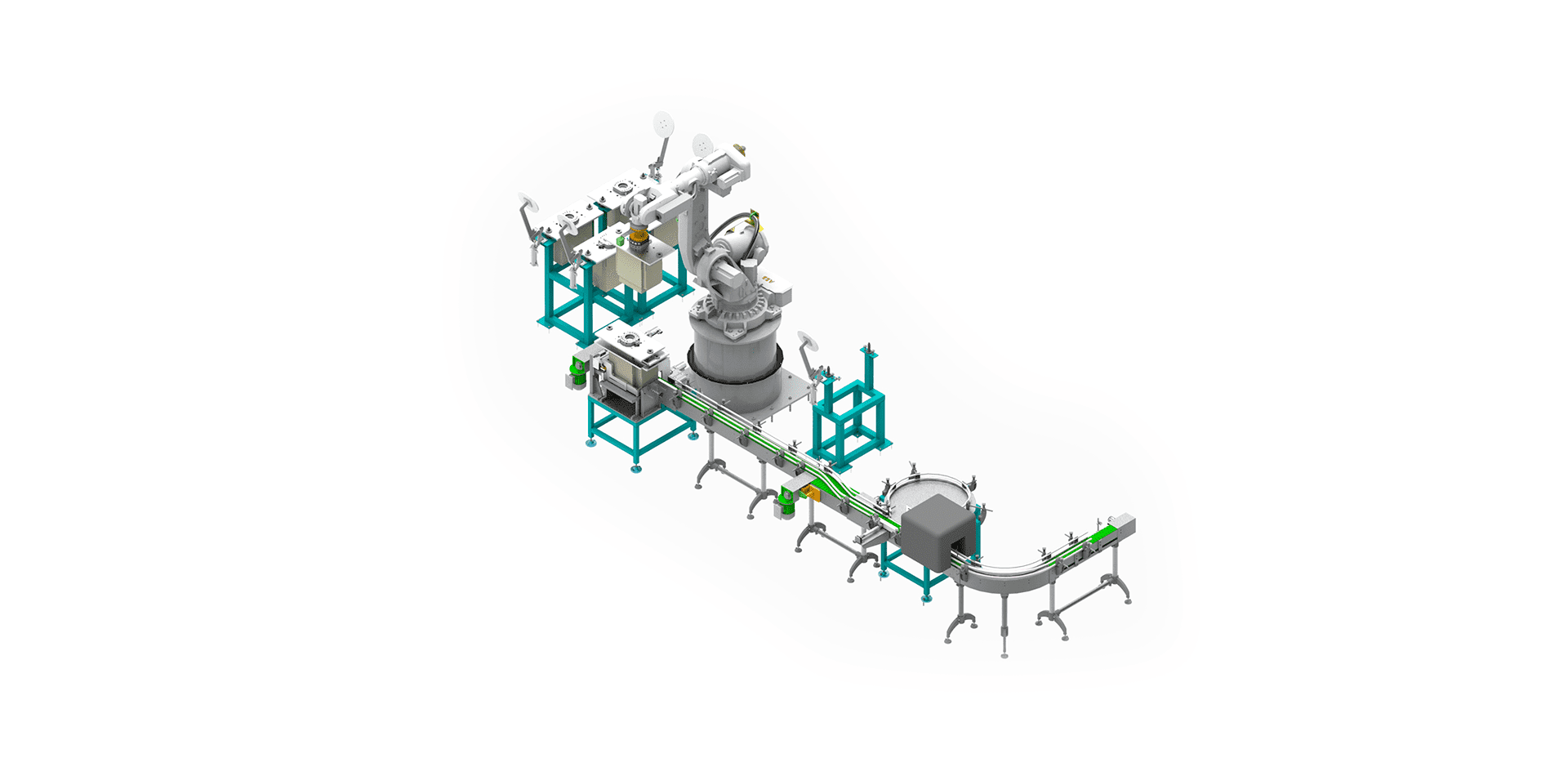

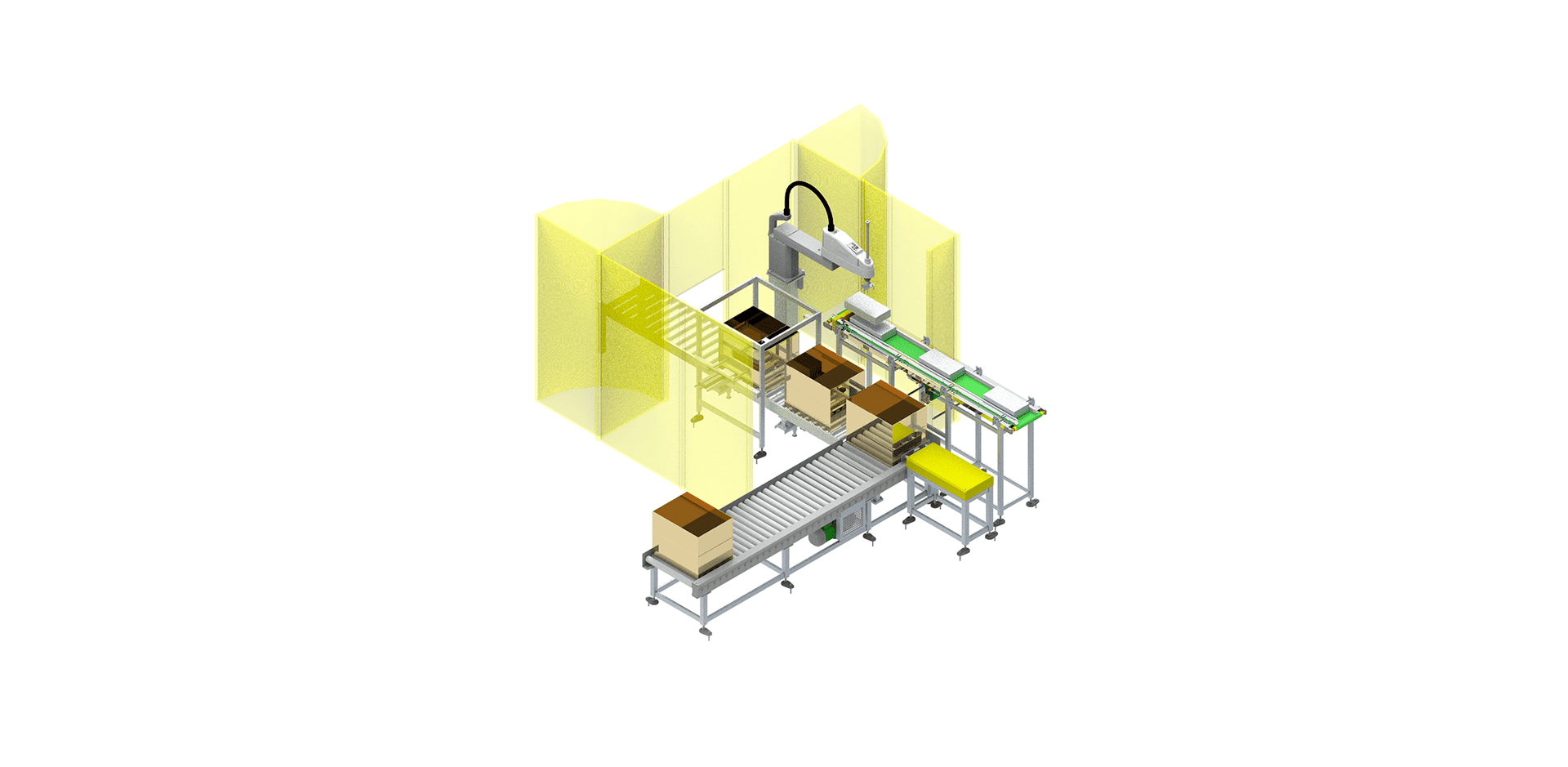

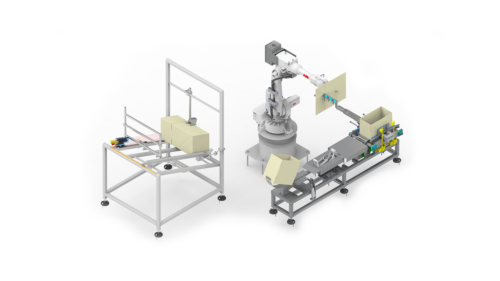

Cybernetik’s ROBO equipment handle diverse operations from pick-place and packing to palletizing and stretch wrapping. Cybernetik Technologies’ ROBO equipment handle diverse operations from pick-place and packing to palletizing and stretch wrapping. Cybernetik’s Robotic Solutions, as demonstrated in their Robotic Pick and Place case study, provide cutting-edge automation technology that enables precise and efficient handling of products, optimizing production processes for various industrial applications. Robotics and automation solutions from Cybernetik drive significant improvements in productivity and operational precision. We are the leading robotics process automation company that enhances efficiency and accuracy across various industries.