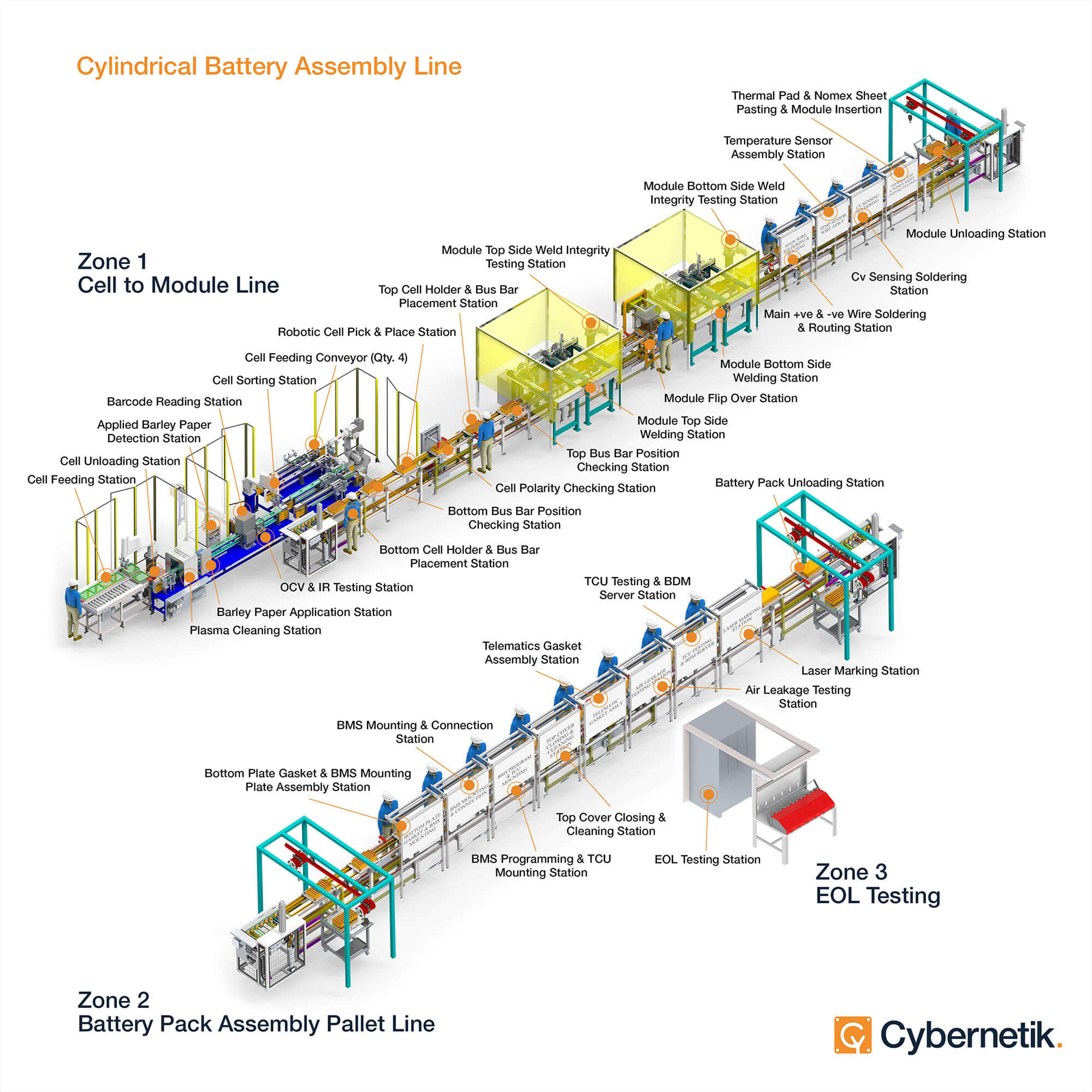

We develop efficient Turnkey Solutions for your EV business

"*" indicates required fields

Cybernetik is an industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the food, pharmaceutical, chemical, and manufacturing industries across the world.

Cybernetik was set up as a consultancy in 1989 by a group of engineers from the Indian Institute of Technology (IIT)-Madras, India and the State University of New York at Buffalo, USA.

From 10 people operating in less than 100 sq.m. workspace, our footprint in India has expanded to 30,000+ sq.m. across four units, two each in Pune, Maharashtra and Nadiad, Gujarat.

Our global operations are based out of three international offices:

Vietnam (for Southeast Asia), Dubai (for Middle East and Africa) and United States (for North America).

Notifications