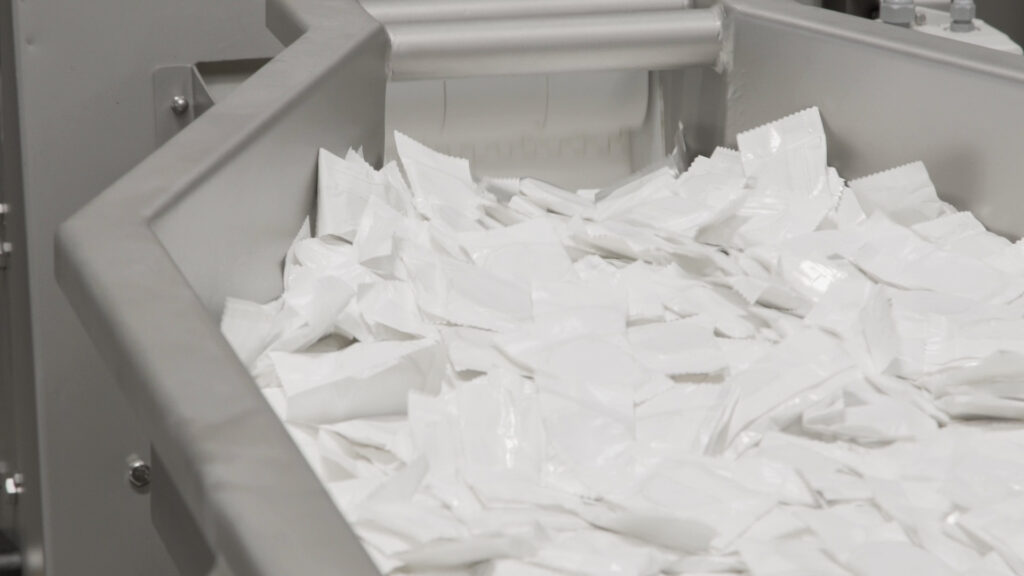

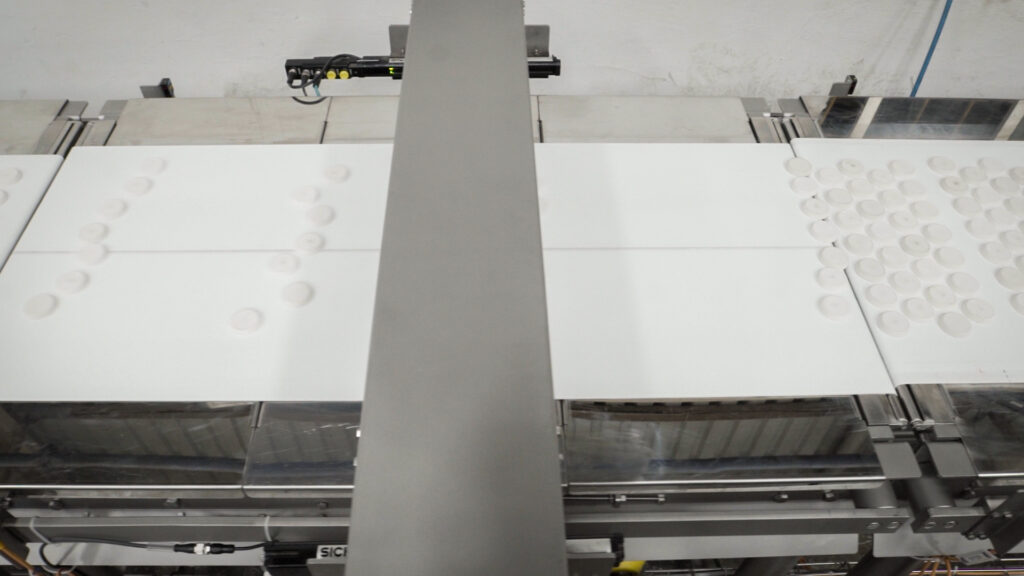

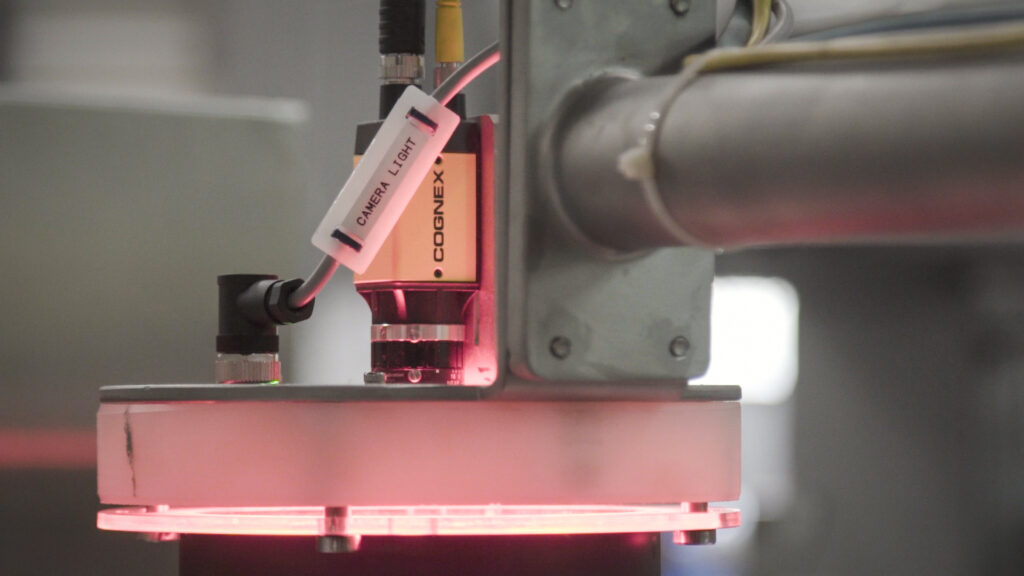

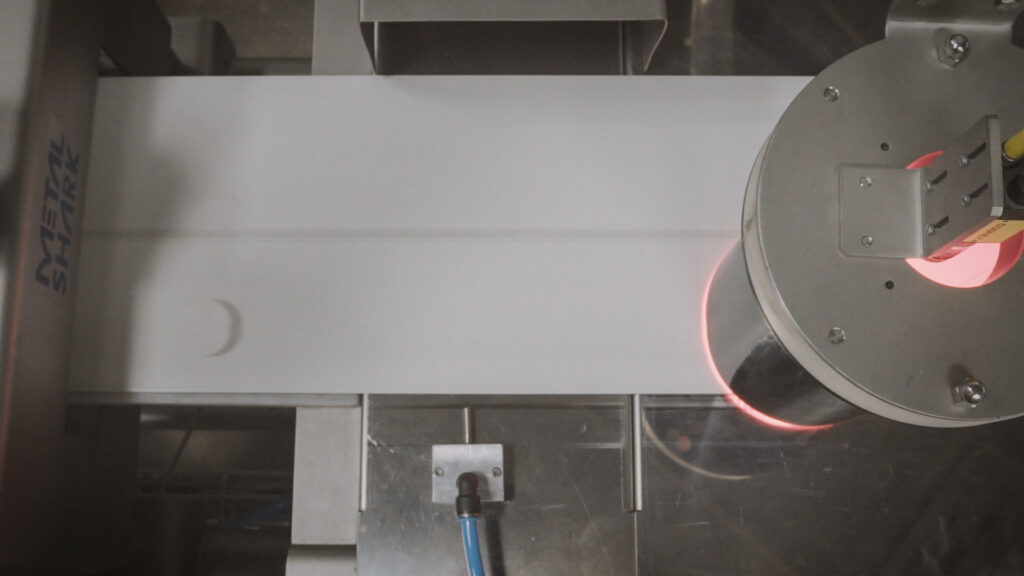

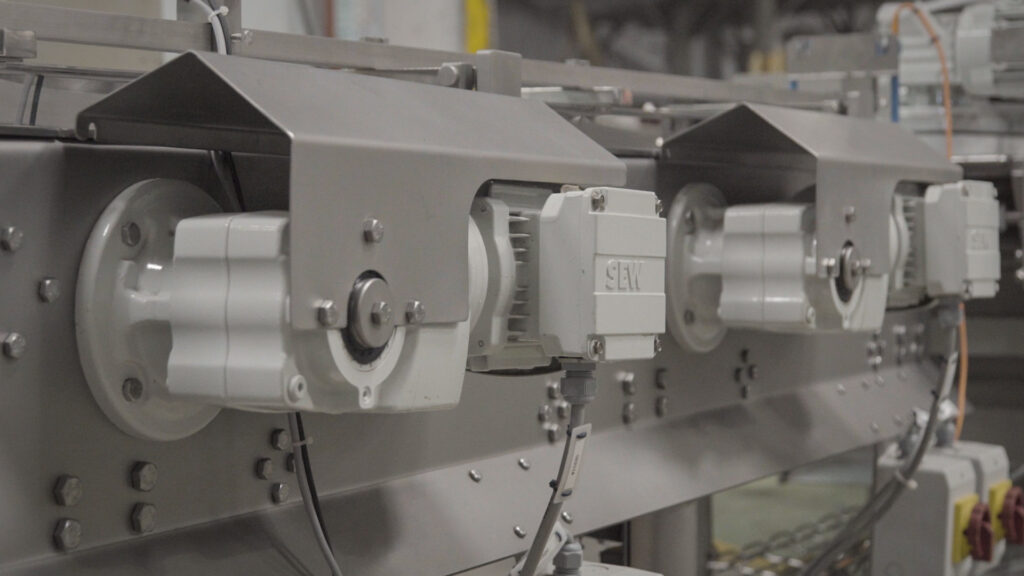

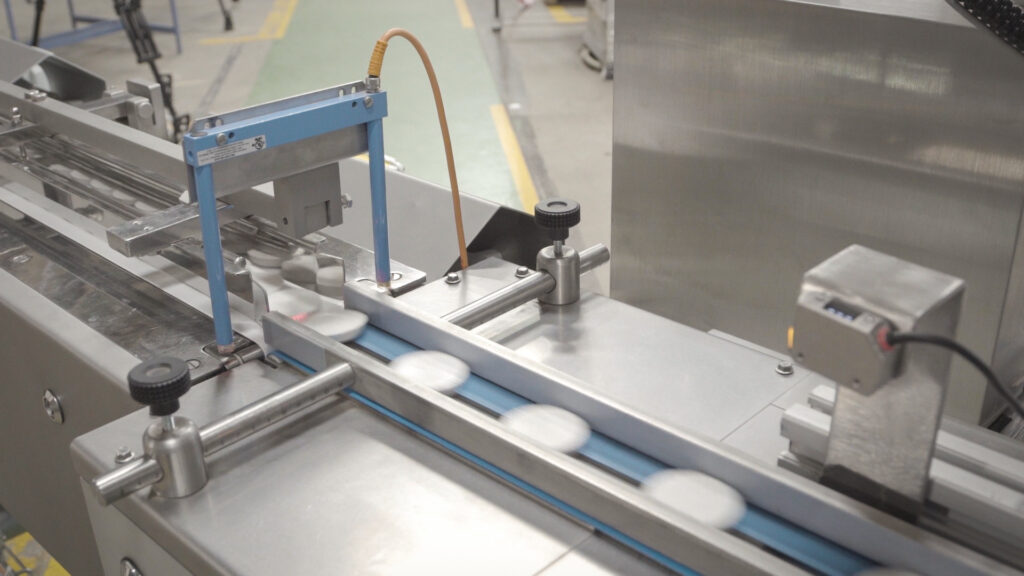

Relevant for primary, tertiary, and secondary packaging automation manufacturers. Completely turnkey, our solution delivers 1800 PPM throughput with auto distribution balancing on wrapper feedback. Main PLC Panel with HMI enables recipe selection and fresh recipe configuration. Made from food grade SS304, it complies with all relevant global safety standards.

The future

of automation is here.

Food

16 weeks

Cybernetik is among the top manufacturers of primary, tertiary, and secondary packaging automation systems. Packaging is an area where machines hold an inherent upper hand over humans, given the repetitive nature of the task and the necessity of high degree of accuracy. It is precisely this natural advantage that Cybernetik harnesses.

Before getting deeper in the packaging arena, let us understand the subtle differences between various stages of packaging:

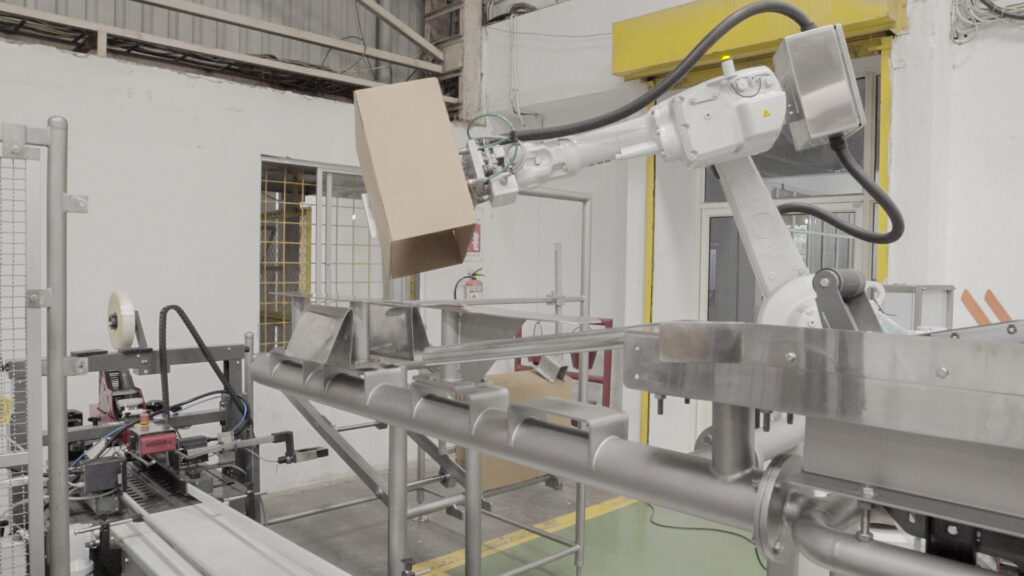

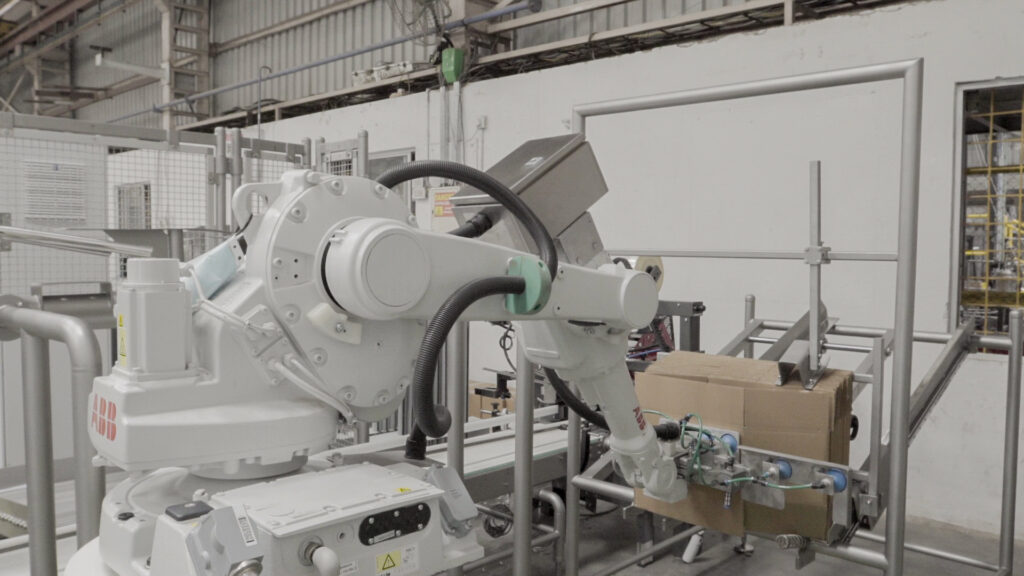

Many times, the same machines are used for different packaging stages. A case packer that loads primary packed chocolates (or biscuits) into cases (or cartons) will be an example of secondary packaging automation. But if the same case packer is handling double packed chocolates, it becomes a tertiary packaging automation system.

Because secondary packaging is a robot friendly area, secondary packaging automation is, by its very nature, an efficient mechanism. Secondary packaging is usually the first part of a product package that a prospective buyer views. This makes it significant from the branding point of view. Therefore, it not only serves the usual protective function but also the purpose of catching a prospect’s eye.

The other function of secondary packaging is logistical – it collects multiple primary packaged products into a stock keeping unit (SKU), simplifying the storage, transportation, and record keeping of products.

Further extending the compatibility between secondary packaging and automation, a study found that secondary packaging registered the highest and quickest growth from among all the packaging areas that boosted throughput using robots. The study was titled, “Robotics 2019: Innovation 2 Implementation,” and focused on industries in North America.

Cybernetik Solution