Electric Vehicles (EVs) are crucial in the fight against Global Warming & Climate Change because transport is a sector tough to decarbonize. Welding becomes important as it has a direct bearing on the safety, performance, and throughput of EV batteries.

Electric Vehicles (EVs) & the Decarbonisation of Transport

Welding technology used for EV battery assembly must minimize the cell-to-tab electric resistance for top battery performance and safety [1]. Thermal runaway is always a hazard given the hyper energy density of EV batteries [2]. Improper connection escalates this risk by increasing the cell-to-tab resistance [3].

Engineers choose the weld technology based on the production scale, battery cell geometry, and cost [1]. Weld joints have strength comparable to the parent material’s, making welding a preferred joining method [4].

EVs help decarbonize road transport, a tough task [6]. The sector emits 16% of the world’s greenhouse gases (GHGs) [5]. The Paris Agreement mandates limiting temperature rise to 1.50C [7] above the pre-industrial levels to avoid runaway Climate Change. This requires Net Zero Emissions by 2050 [7].

Net Zero requires 300 million electric cars in the world by 2030 [5]. As of end-2022, there are around 26 million EVs (including hybrids) [8]. Although improvements in EV range, policy support, and public spending have fuelled the recent EV demand, making 2021’s worldwide weekly sales exceed 2012’s annual sales [9], this is not enough.

China hosts 46%, Europe 34%, and the United States 15% of the worldwide EVs. Eventually, these markets will saturate. India, Southeast Asia, Brazil, Japan, and Mexico will then drive the demand. More than 50% of new sales of India’s 3-wheelers are electric. Latin America is rapidly electrifying taxis. Vietnam is fast migrating to electric bikes [8].

Welding Technologies for EV Battery Assembly

Assembling lithium ion batteries is complex. These batteries have multiple layers with countless joints, and house different metals of varying thicknesses [10]. Welding technology used for EV battery assembly must deliver:

High quality welds are of uniform width and have no gaps. Thin welds are more suited for EV battery packs. Thicker ones can penetrate the casings. Proper welds address the following welding challenges [1] & [10]:

Technologies used for EV battery welding are:

Weld quality depends on [12]:

Following features of the EV battery welding set up determine weld quality [12]:

Equipment or system designers prefer the following communication protocols to achieve the transmission speed, processing capability, storage space, and networking that Industry 4.0 solutions demand [12]:

Resistance Spot Welding utilizes [1]:

| Pros | Cons | Compatibility with Battery Types |

|---|---|---|

| Automation friendly | Limitations in joining high conductivity materials | Small Prismatic |

| Does not require shielding gas or filler | Limitations in dissimilar metal welding | Cylindrical |

| Contact process enables excellent quality control | Electrode sticking to base metal | |

| Contact process eliminates need for fixtures | Quality variance between different welds | |

| Low capital requirements | Slower | |

| Compatible with thin sheets |

Three main process parameters for spot welding are [1]:

Weld current is critical to weld quality, and needs to be focused. Electrodes with dome-shaped ends are used to focus the current. Low applied current fails to counter stray current from battery sources while excessive levels cause electrode sticking. Weld current is affected by [11]:

AI integration in RSW maps the relationship between weld parameters and quality. Apart from decreasing quality variations, automation slashes RSW’s operational expenses related to [1]:

Factors that improve RSW quality are:

Monitoring electrode wear is the chief quality-related concern for RSW after process optimization [12]. Welding guns and power sources form the main capital expenses, making it less costly than others. Inverters slash operational expenses by improving uptime, quality, and yield [1].

Throughput is usually around 1 weld per second, and depends on:

RSW is not suited for welding [1]:

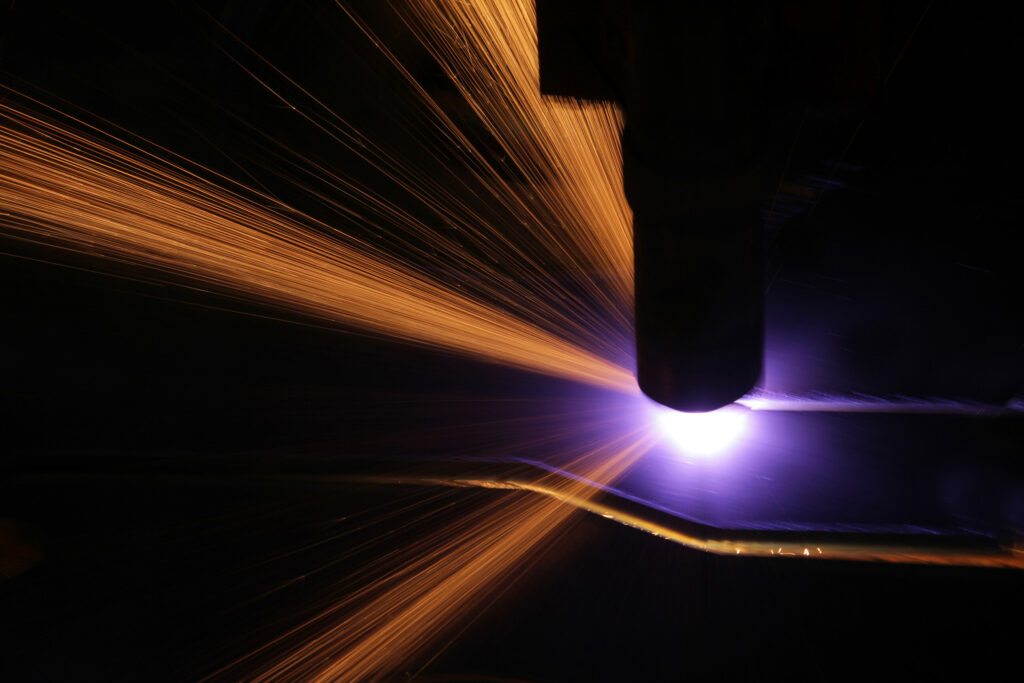

Laser Beam Welding uses a highly focused, minimally diffracted beam with a tiny spot size. Hyper beam intensity causes surface metal atoms to evaporate and generate vapour pressure, which creates a keyhole i.e. a depression in the molten material. The keyhole and the beam reflections inside the cavity boost the energy efficiency of laser welding [1].

| Pros | Cons | Compatibility with Battery Types |

|---|---|---|

| Automation friendly, being a non-contact, simple-to-imitate process | Complex execution requires dedicated experience and training | Prismatic |

| Low electrical resistance joints | Excellent joint fit-up essential | Cylindrical |

| Fast | Tough to weld high reflectivity metals | Pouch |

| Accurate | Capital intensive | Ultra Capacitor |

| Suitable for narrow areas with low accessibility | ||

| Limited heat affected zone | ||

| Suitable for mass production | ||

| Minimal/zero post weld processing | ||

| Easier control over depth and width |

Two primary lasers used for EV battery pack welding are [1]:

Pulse rate, welding speed, and laser power influence [1]:

Other influences on LBW quality include:

Chief concerns for laser weld quality after optimisation are the maintaining of proper [12]:

ANSI 136.1 dictates the use of a non-light-transparent enclosure for laser welding [12]. Thin welds are more suited for EV battery packs. Thicker ones can penetrate casings. Close parameter and process control prevent the high power density of the laser from causing unintended damage [1].

LBW speeds depend on the materials being welded and their thicknesses [12]:

Ultrasonic Welding can be Ultrasonic Metal Welding (UMW) or Ultrasonic Wire Bonding (UWB). The mechanism for UMW is not completely understood. Most likely, a combination of 20 kHz oscillation and pressure form the joint via [1]:

Sheets and foils of diverse metals and varying thicknesses are seam and spot welded via ultrasonic welding. UMW is automation friendly, its parameters can be monitored via software for data analysis, and it fits into existing manufacturing lines [1].

UMW does not melt the metals, and provides joints of the required strength with minimal or no brittle intermetallic zone. Such features make it suitable for connecting metals with high reflectivity and conductivity [13]. The nullification of melting makes it a low energy [14] and, therefore, less expensive process [1].

| Pros | Cons | Compatibility with Battery Types |

|---|---|---|

| Particularly compatible with dissimilar, thin, and numerous layers of metals with high conductivity | Requires access from both sides with anvil on one side and sonotrode on other | Pouch |

| Suited for welding high reflectivity materials | Error prone when welding materials with high surface roughness | |

| No filler metal or shielding gas required | Requires excellent fixtures as vibrations can damage battery cell structure | |

| Joints free from typical metallurgical issues viz. hot cracking, porosity, and bulk intermetallic compounds | Unsuited for hard materials as these do not vibrate much | |

| Solid state welding enables lower energy inputs and shorter weld times | Cannot weld think joints as these do not vibrate much | |

| Lower production cost | Can only weld lap joints as it requires access from both sides | |

| Low energy usage | Sonotrode is prone to sticking as built up metal on its surface bonds with workpieces of same metal |

A variant of UMW, UWB is used widely in microelectronics where access is available from one side only. A sonotrode welds a continuously fed wire to successive substrates via pressure and vibration.

UWB provides the same positives as UMW. However, it requires tight fixtures as lateral movement lowers the amplitude of ultrasonic vibration, so essential for producing robust joints. And because it can weld only small gauge wires, UWB can deal with low currents only [1].

Determinants of UMW and UWB weld quality are [1]:

Weld Technology Selection

Manufacturers choose welding technology based on [1]:

Manufacturing Readiness Level (MRL) of various EV battery related weld technologies are as follows [1]:

Guidelines to select the most compatible method [1]:

Finally

Production scale, battery cell geometry, and budget have the strongest influence on the selection of welding technology. Whichever technology is chosen, the need to minimize the cell-to-tab electric resistance remains constant.

References